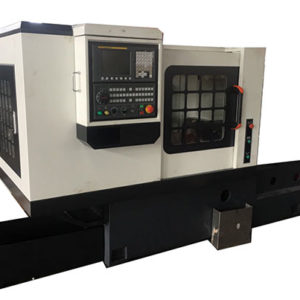

Description

Scope of application

The equipment is suitable for the processing of the head of the long trailer natural gas steel cylinder, rough machining outer circle, inverted inner and outer corners, fine flat end face, finishing inner hole, finishing outer circle, correcting the inner arc wrinkled surface and milling internal and external grain, etc., the above processing is realized by numerical control programming, which is an ideal equipment for the head processing of long trailer natural gas steel cylinder. The machine meets the following basic requirements:

● Workpiece diameter is 590-$920 (customizable), length is 3m-12.3m (customizable), weight ≤ 5t cylinder mouth thread processing.

●Processing thread specifications: internal thread G3, M7O-90×3H, external thread G5B, its accuracy is performed in accordance with the standard GB/T7307.

●Meet the requirements for the thread processing of cylinders made of high-quality carbon structural steel, alloy structural steel, high-strength steel and other pipe blanks with hardness of HB200-400, including 30CrMo, 35CrMo, 40CrMo, high-strength steel, titanium alloy, etc.

●Production cycle: 30-45min/station.

●Reasonable clamping method, complete rough, finishing, thread processing process; The processing method adopts the workpiece non-rotation method to improve the processing accuracy.

●The numerical control system adopts Siemens 828D (can be equipped according to the manufacturer’s requirements), and the servo motor adopts Siemens to improve the interpolation accuracy and operation speed.

Reviews

There are no reviews yet.