1. What’s hot spinning technology?

“Hot spinning” involves spinning a piece of metal on a lathe while high heat from a torch is applied to the workpiece. Once heated, the metal is then shaped as the tool on the lathe presses against the heated surface forcing it to distort as it spins. Parts can then be shaped or necked down to a smaller diameter with little force exerted, providing a seamless shoulder.

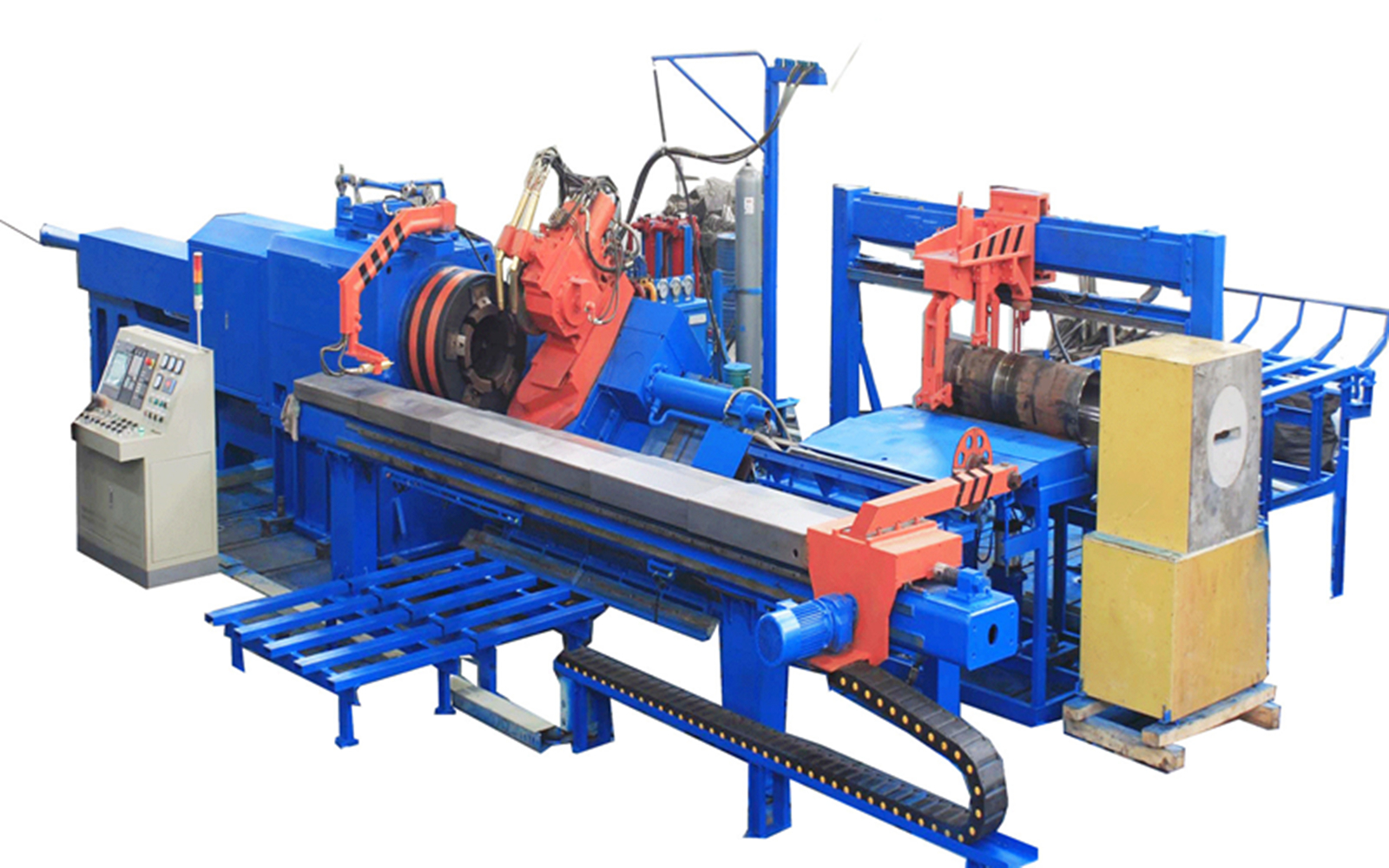

2:World best hot spinning machine

Hot spinning machine is well known as pipe neck-in and closing machine. We have dozens of leading domestic patented technologies, our company has strong technical strength and rich experience, and has a scientific and technological team that is proficient in hot spinning technology. The machines are highly praised by domestic and foreign customers and we have exported to Europe, Asia and Africa,including over 10 countries.

Our machines cover all diameter seamless cylinders, like fire extinguisher, oxygen cylinder, CNG cylinder, tank trailer (long pipe), the maximum diameter we can produce is 920mm and the maximum length we can produce is 12500mm.

3: Different hot spinning technology

According to different requirements, we research and develop different forming principles for producing the seamless cylinder.

Template type:

– Speedy mouth/bottom closing forming

– Full automatic operation with conveyor

Roller type:

– Uniform and smooth for mouth/bottom closing forming

– Full automatic operation with conveyor