Description

Machine Introduction

Equipment body size: 10600mm×4000mm×3200mm (L×W×H, including filament decoiler + dipping unit + filament winding unit)

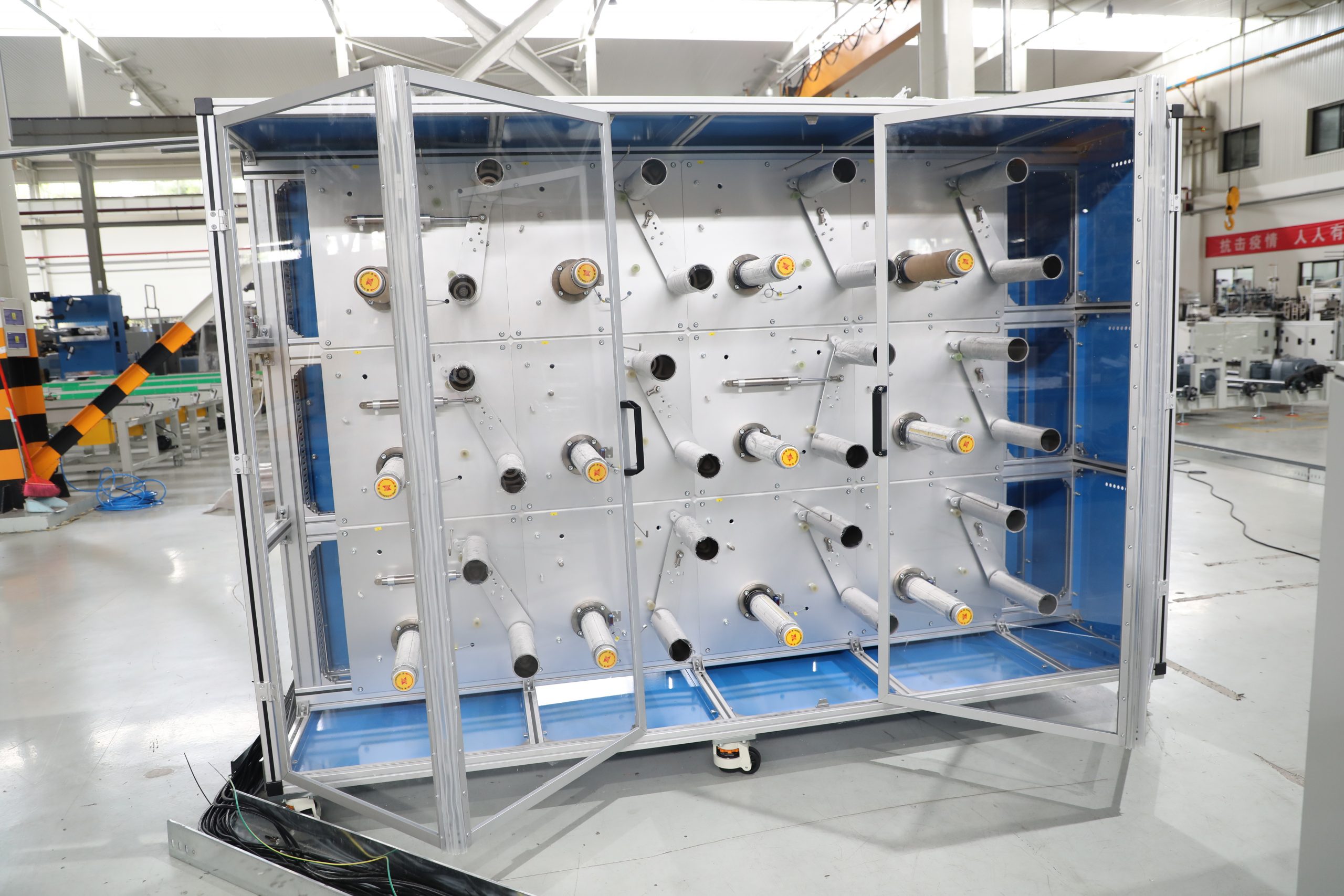

1.The main body of the wire rack is made of aluminum profile splicing structure. 2.12 spindles per unit, each spindle is equipped with an active wire feeding motor. 3.The fiber weight of each spindle is up to 12Kg, and the outer diameter is up to φ270mm, with tension control. 4.The threaded hole ceramic ring is made of ceramic material (consumable parts). 5.Install closed sliding doors, improve the material of doors and guide rails, and improve durability and firmness.

No. | Name | Parameters |

1 | Bobbin Size | Inner diameter Φ76; tube length 280~290 (mm) |

2 | Carrier specifications | The maximum does not exceed 12kg; the maximum outer diameter does not exceed Φ270mm |

3 | Carrier number | 12 |

4 | Bobbin tensioning method | Pneumatic expansion |

5 | Tension range | 10N~50N, constant tension control |

6 | Unwinding speed | ≤1500mm/s |

7 | Control system | Siemens PLC; servo motor |

8 | Equipment weight | About 1.3 ton |

1.The main body of the dipping unit adopts a welded structure, and the surface is sprayed with anti-corrosion treatment. 2.After impregnated with resin glue, the single fiber filaments are assembled into a large tow, and the large tow is directly 3.wound onto the workpiece by the winding machine after being controlled by the bus tension of the dipping machine. 4.The dipping is all passive rollers with rubber control blades. 5.The insulation of the dipping tank is heated by circulating water. 6.The dipping tank is made detachable for easy cleaning.

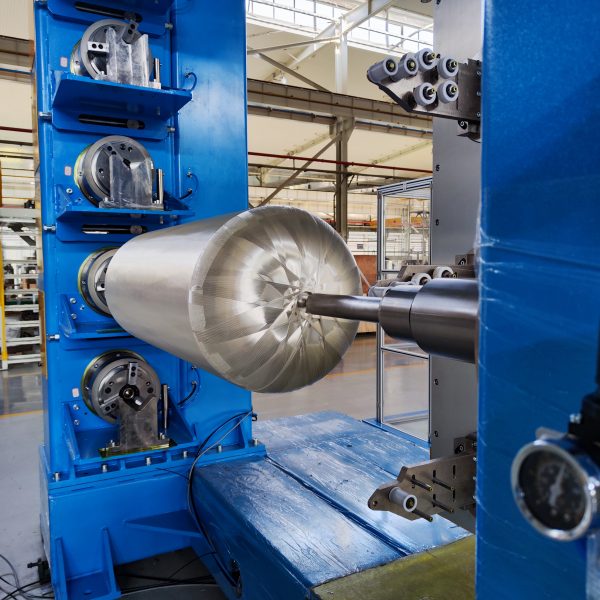

1.The main body of the winding unit adopts a welded structure, and the surface is sprayed with anti-corrosion treatment. 2.Pneumatic chuck clamping can realize automatic loading and unloading. 3.Winding diameter: maximum Φ200mm. 4.Winding length: 300-600mm. 5.Spindle revolutions: 0~100r/min. 6.The threaded hole ceramic ring is made of ceramic material (consumable parts). 7.Multi-axis CNC system, AC servo motor control. 8.Automatic cutting and feeding functions are optional.

No. | Name | Parameter |

1 | Number of winding stations | 3,4,5 station according to your production capacity |

2 | Spindle revolutions | 0-100r/min |

3 | Number of filaments | Max 8 |

4 | Gas cylinder clamping method | Pneumatic chuck automatic clamping |

5 | Tension range | 15N~250N |

6 | Winding speed | ≤1500mm/s |

7 | Control system | Siemens PLC, servo motor |

8 | Equipment weight | About 7.5 ton |

Reviews

There are no reviews yet.