Description

Product Description

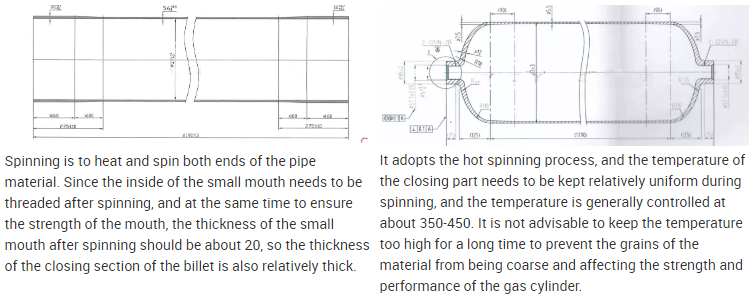

The cylinder blank is generally prepared by the reverse extrusion process. Due to the limitation of the process, the wall thickness is generally relatively thick, usually about 18-24mm, while the gas cylinder requires a wall thickness of about 5-7mm, and the general thickness of the bottle mouth closing part needs to be 10- 12mm, so a strong spin is required for thicker blanks.

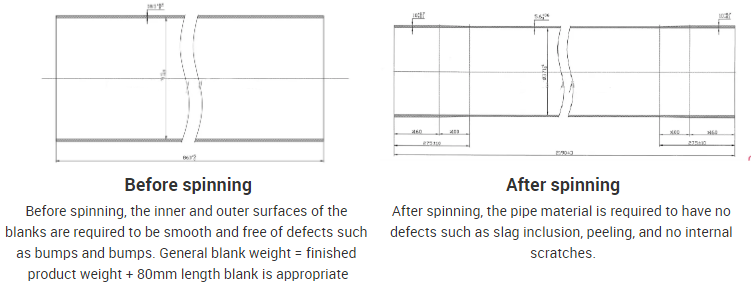

Step1: Tube strong spinning

1. The inner and outer surfaces of the strong coil blank should be smooth, and no defects such as cracks, corrosion, inclusions, peeling, bubbles, abrasions, bumps, scratches, folds, straights, pits, etc. are allowed.

2. Internal surface quality requirements: roughness Ra2.0, the surface has no defects such as cracks, pits, heavy skin, bumps, scratches, etc., and the grinding lines on the inner wall are consistent (circumferential).

3. The straightness of the strong coil is not more than 0.15%.

Step2: Tube closing

Technical drawing

Details

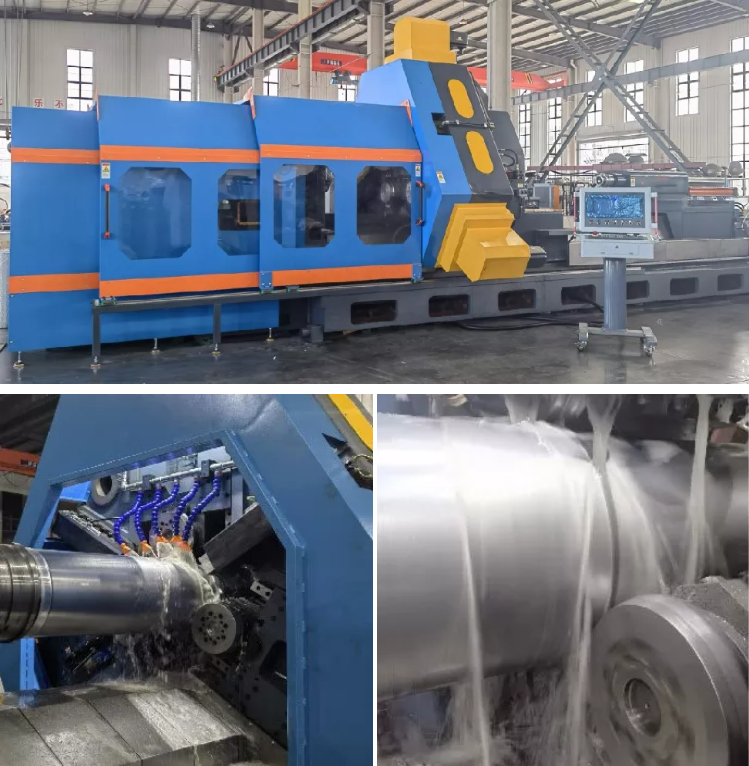

Tube strong spinning

Technical requirements | Related parameters |

Spinning equipment | Three-wheel CNC spinning machine |

Diameter of spinning machine | 600mm/800mm |

Length of spinning machine | max. 3200mm |

Spinning method | Three-wheel spinning |

Spinning temperature | Room temperature, special coolant |

Tube closing

Technical requirements | Related parameters |

Spinning equipment | Special CNC closing and spinning machine |

Maximum closing diameter | 460、640 |

Maximum length | 3500mm |

Spinning temperature | ~450 |

heating method | flame heating |

single cylinder time | 12min*2ends |

Loading and unloading method | Optional manipulator |

Related products

Reviews

There are no reviews yet.