Description

Product Description

Technical specification

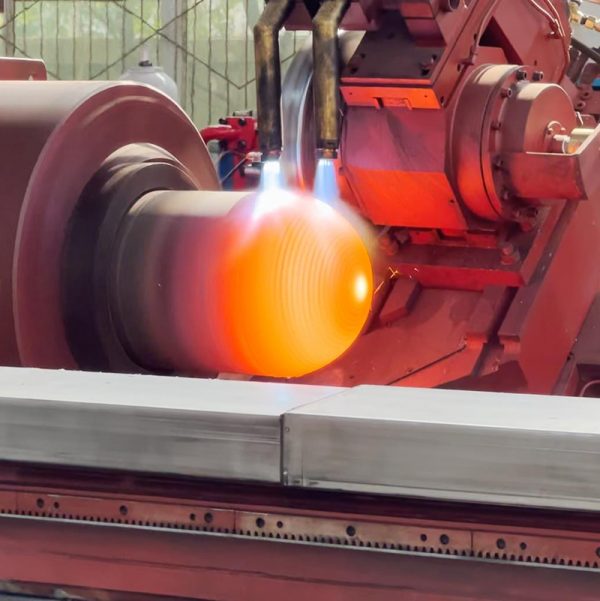

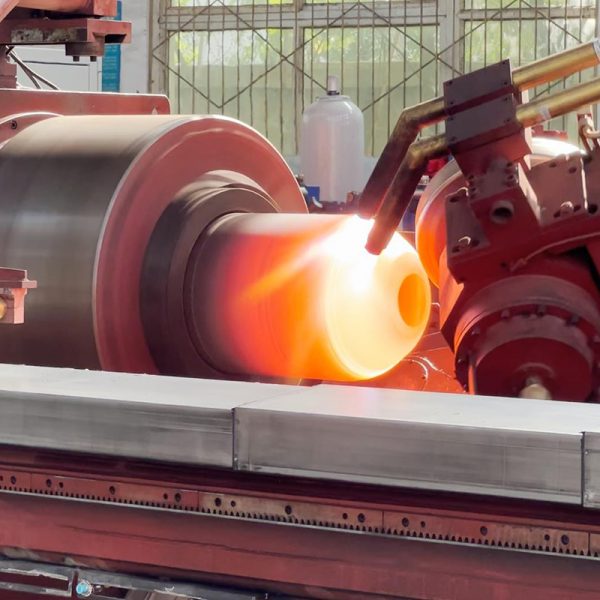

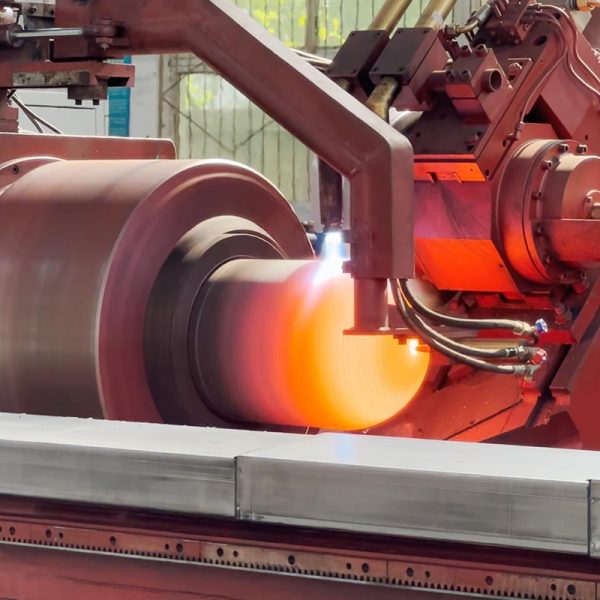

This machine is designed for cylinder’s necking-in and bottom closure of high pressure cylinders, CNG cylinder as well as the other pressure vessels. The maximum applicable diameter is 406mm, and the maximum spinning length is 2000 mm, its controlling system adopts Siemens PLC.

| Spinning diameter | Max. 406mm |

| Spinning diameter | Min. 232mm |

| Spinning length | Max. 2000mm |

| Spinning length | Min. 800mm |

| Starting wall thickness | Max. 15mm |

| Starting wall thickness | Min. 5mm |

| Spinning cycle (incl. load/unloading/necking-in) | Max. 2.5min |

| Equipment centre height | 1235mm |

| Main spindle drive | 144KW |

| Axial stroke of sliding block | 65mm |

| Radial stroke of sliding block | 17mm |

| Radial clamping force | 1200KN |

| Main spindle speed (Variable) | 0-600rpm |

| Axial feed force of die | 246KN |

| Max. mould axial feed-in speed | 30°/s |

| Mould rotating angle | 0-100° |

| Hydraulic motor | 90KW |

| Proportional speed regulated reversing valve | Italy ATOS |

| Control | Siemens |

| Connected electrical load | 3*380V, 50Hz |

| Heating power of the pipe end | 500KW/1000Hz |

| Connected pneumatic load | 6 bar |

It is mainly composed of conveying mechanism, intermediate frequency heating system, feeding device, spindle mechanism, rotary die device, turning device , automatic heating device, discharging device and discharging pusher , hydraulic system , electrical system , thin oil Lubrication system , etc.

It is mainly composed of conveying mechanism, intermediate frequency heating system, feeding device, spindle mechanism, rotary die device, turning device , automatic heating device, discharging device and discharging pusher , hydraulic system , electrical system , thin oil Lubrication system , etc.

The conveying mechanism is mainly composed of a material distribution rack, an intermediate frequency heating table, a clamping heating trolley, a feeding rack, and a feeding rack.

After the blanking is completed, the fixed-length tube blanks enter from the conveying line and are arranged on the distribution rack. 4-5 billets can be stacked at the same time. After the distribution mechanism, one at a time enters the intermediate frequency heating bench, and the clamping heating trolley will The tube blank is clamped into the intermediate frequency induction furnace. After the heating temperature is in place, the clamping heating trolley will hold the tube blank and drag it out of the intermediate frequency furnace. The groove is ready for spinning.

The conveying mechanism is simple in structure and quick in execution. The clamping and heating trolley adopts a high-rigidity single-girder box-beam side support structure, which is not easy to deform, multi-point support, and runs more smoothly. The motor and the frequency converter perform the action, the speed is adjustable, and the anti-overlap device is installed on the clamping frame to avoid the over-lap of the heating short pipe. A geared motor is installed under the heating platform, and the roller is driven by the chain to realize the low-speed rotation of the tube blank and the forward and reverse heating, so as to avoid the phenomenon of uneven heating of the tube end.

Related machines

well as threading, which are realized by NC programming.

2.Single station device is adopted for input and output materials(semi-automatic); 3.The work piece clamping adopts the front top

bowl positioning.

1. The fuselage is a steel plate welded structure, which requires good rigidity and stability. The fuselage weighs about 8 tons

(excluding hydraulic system and loading and unloading systems).

Reviews

There are no reviews yet.